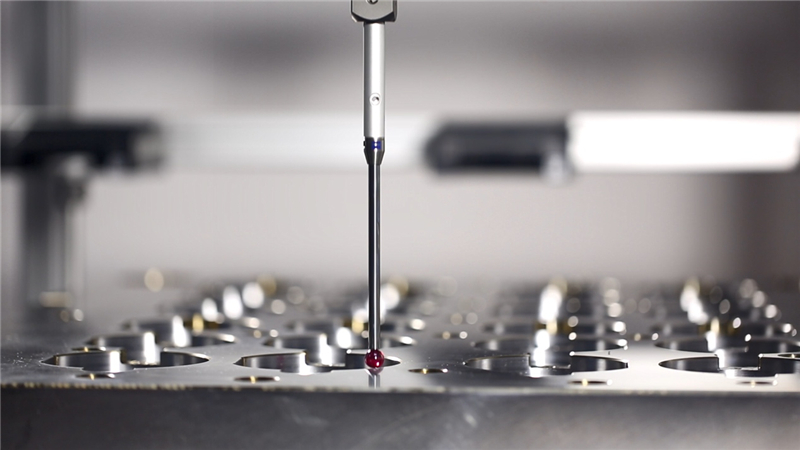

Quality Control

YESE STAR PLAST yakagadzira yayo yakakwana kugadzira uye manejimendi system. Kune kwakasimba kwehutongi hwekutonga manejimendi mune yega yega maitiro. Isu tinoedza nepatinogona napo kuti tidzivise kukanganisa, uye kumisa kuwedzera kukanganisa kune inotevera process.Iyo nhanho kubva pakugadzira dhizaini uye kuongororwa kwezvigadzirwa zvepurasitiki kusvika pakutsvagisa pamusoro pekugoneka kwekugadzira mold, kubva pakutenga zvinhu kusvika pakuongororwa kwemhando yezvinhu, kubva pakugadzirisa. tekinoroji kusarudzwa uye kurongeka kusvika pakuongororwa kwemhando, kubva pakuunganidza mold uye kuisirwa kuenda ku mold test, etc. Chimwe nechimwe chinongedzo chinofanirwa kuve chechokwadi chisina hurema, uyezve isu tinokwanisa kuchengetedza akaunzwa mold akakodzera.